Types of commonly used roof truss

Types of commonly used roof truss

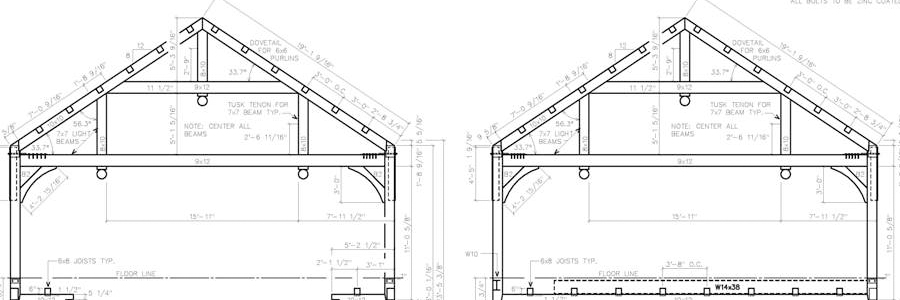

Roof trusses carry the roof and push loads down to the walls. The right choice depends on span, roof pitch, internal layout, and the need for open space under the rafters.

Most homes use factory made trusses for speed and consistency. Site built frames still suit small jobs and heritage work. The goal is simple: keep the roof stiff, control movement, and give the room below the shape it needs.

Short spans suit simple trusses. Long spans need stronger webs.

Think about access, services, and loft use before you pick a type. A little planning saves time later and avoids costly changes once the roof is up.

Below are the trusses you will see most often with plain notes on when they work best and what to watch for on site.

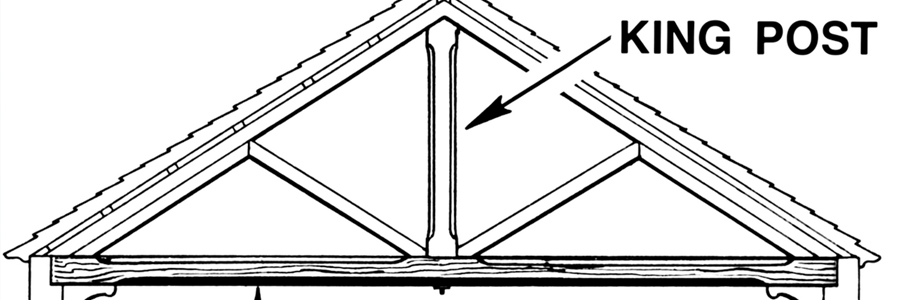

King post truss

This is the classic choice for short spans. One central post ties the ridge to the tie beam with simple struts to the rafters. It is quick to set out and easy to read on site.

Use it for small rooms or porches where clean lines matter. Keep connections tight and protect end grain from moisture at the wall plate.

Queen post truss

Two posts instead of one give a wider clear center. It bridges longer spans than a king post and can frame a neat ceiling feature.

Good for rooms that need a central walkway or a roof light. Watch deflection at mid span and brace the rafters well during install.

Fink truss

The most common house truss. The W shaped web spreads load with good material economy which keeps weight down and cost under control.

Ideal for standard roofs with no room-in-the-roof. Leave clear routes for cables and pipes at the eaves and never cut webs to make space.

Howe truss

Suited to larger spans and heavier finishes. Diagonals in compression and verticals in tension handle loads well where roof coverings are heavier.

Use where the roof pitch is modest and wind lift is a concern. Ensure bearings are full and plates sit flat on the wall plate.

Pratt truss

Opposite action to a Howe. Diagonals take tension and verticals take compression. It works well for steady uniform loads.

Pick it where services need simple straight runs. Keep nail plate seating clean and dry during lifting and storage.

Attic or room in the roof truss

Creates usable space within the rafters. The web layout forms floor joists and side frames so you can finish a loft without heavy steel.

Plan stair position early and check headroom at the ridge. Allow for service runs and insulation depth at the eaves.

Raised tie and scissor truss

These lift the ceiling line. A raised tie opens the room edge to edge while a scissor gives a vaulted effect with opposing rafters.

Great for light airy rooms. Check thrust at the wall line and confirm fixings for ceiling finishes that follow the rake.

Metal plate connected trusses

Most modern trusses use pressed plates. Factory control gives repeatable quality and fast install on site.

Store flat on level bearers and cover from rain. Never drill, notch, or cut members. If a change is needed speak to the supplier.

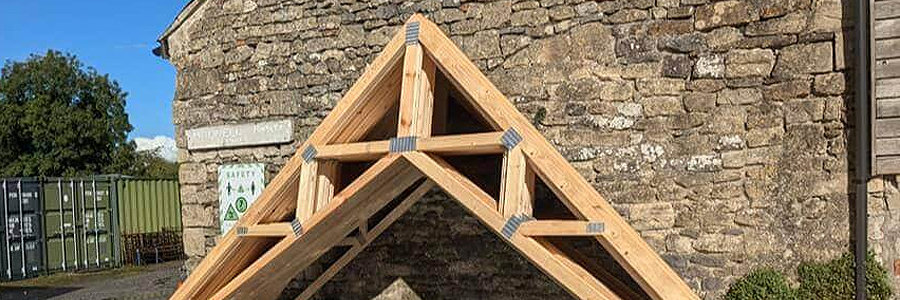

Heritage and project checks

Older buildings may need a tailored approach. Wall plates, bearings, and tie levels can vary which affects how a truss sits.

Confirm span, pitch, and loadings before you order. Agree lifting points, bracing, and temporary works. A clear plan keeps the roof straight and the programme on track.